Search by Purpose

- Printing

- Scanning for Sending

- Using Fax

- Sending a Fax through a Computer (PC-Fax TX)

- Using Fax in the Network Environment

- Copying

- Specifying the Color and Image Quality for Copying

- Saving the Number of Copy Sheets

- Specifying the size or type of the paper to be copied

- Finishing in Handouts or Booklet Format

- Specifying the Original Size and Scanning Method

- Copying Various Types of Originals

- Adjusting the Layout for Copying

- Inserting a Front Cover or Blank Sheet into Copied Documents

- Adding a Text or Image to the Original

- Erasing an unnecessary portion for copying

- Restricting the Secondary Copy of Copied Paper

- Saving to a User Box when Copying

- Using User Boxes (Hard Disk) on this Machine

- Registering and Managing Destinations

- Fully Using Functions of this Machine

- Configuring the Operating Environment of this Machine

- Configuring Basic Information of this Machine (For Administrators)

- Managing the Power Supply for Power Saving (For Administrators)

- Customizing the Control Panel Environment

- Viewing the Operation Conditions and Settings of this Machine

- Configuring Reset Operations (For Administrators)

- Configuring Original Scan and Output Operations

- Adjusting Printing Troubles (For Administrators)

- Collecting Information of this Machine to Resolve Troubles Early (For Administrators)

- Configuring the Network Settings of this Machine (For Administrators)

- Configuring User Authentication and Account Track

- Improving the Security of this Machine (For Administrators)

Adjusting Printing Troubles (For Administrators)

To adjust the level to highlight the original background ([AE Level Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [AE Level Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the AE (Auto Exposure) level.

Tap [Higher] or [Lower] to adjust the automatic exposure to one of the five levels. The larger the number, the darker the background.

[2] is specified by default.

To adjust the print starting position or print image troubles ([Printer Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Printer Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the print start position and defective print images.

Settings | Description |

|---|---|

[Leading Edge Adjustment] | Adjust the print start position at the leading edge of the paper relative to the paper discharge direction. For details, refer to Here. |

[Centering] | Adjust the print start position on the left edge of the paper relative to the paper discharge direction. For details, refer to Here. |

[Leading Edge Adjustment (Duplex Side 2)] | Adjust the print start position at the leading edge of the back side of the paper relative to the paper discharge direction for printing the back side in 2-sided printing. For details, refer to Here. |

[Centering (Duplex 2nd Side)] | Adjust the print start position at the left edge of the paper relative to the paper discharge direction for printing the back side in 2-sided printing. For details, refer to Here. |

[Erase Leading Edge] | Adjust leading edge erase width. For details, contact your service representative. |

[Vertical Adjustment] | Adjust the feed direction zoom ratio of paper types. For details, contact your service representative. |

[Media Adjustment] | Adjust print defects (voids, white spots, roughness) that are caused by paper properties for each paper type. For details, refer to Here. |

To adjust the staple, punch, or fold position ([Finisher Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Finisher Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the staple, punch or fold position.

Settings | Description |

|---|---|

[Center Staple Position] | If the staple position is not on the fold line on saddle-stitched paper, use this option to align the staple position on the fold. For details, refer to Here. |

[Half-Fold Position] | If the half-fold position is not on the exact center of the paper, use this option to align the fold on the center. For details, refer to Here. |

[1st Tri-Fold Position Adjustment] | If the tri-fold positions are not located evenly, use this option to adjust the first fold position. For details, refer to Here. |

[2nd Tri-fold Position Adjustment] | If the tri-fold positions are not located evenly, use this option to adjust the second fold position. For details, refer to Here. |

[Tri-Fold Output Setting] | Use this option to select whether to output tri-folded paper to the normal position or a position further away from the normal position set for this machine. For details, refer to Here. |

[Punch Vertical Position Adjustment] | If the positions of the punch holes on the paper are displaced vertically, use this option to adjust the punch hole positions. For details, refer to Here. |

[Punch Horizontal Position Adjustment] | If the positions of the punch holes on the paper are displaced sideways, use this option to adjust the punch hole positions. For details, refer to Here. |

[Punch Regist Loop Size Adjustment] | If the positions of the punch holes on the paper are not in parallel with the paper edge, use this option to correct the obliquity of the paper to make them parallel. For details, refer to Here. |

[Punch Edge Sensor Adjustment] | Use this option to adjust the sensor of the Punch function to detect the edge of the paper. For details, refer to Here. |

[Vertical Punch (Z-Fold) Position Adjustment] | If the positions of the punch holes on the paper are displaced vertically, use this option to adjust the punch hole positions. For details, refer to Here. |

[Horizontal Punch (Z-Fold) Position Adjustment] | If the positions of the punch holes on the paper are displaced sideways, use this option to adjust the punch hole positions. For details, refer to Here. |

[1st Z-Fold Position Adjustment] | Use this option to adjust the 1st Z-fold position. For details, refer to Here. |

[2nd Z-Fold Position Adjustment] | Use this option to adjust the 2nd Z-fold position. For details, refer to Here. |

[Punch Unit Size Detect Sensor] | Use this option to adjust the sensor of the Punch function to detect the edge of the paper. For details, refer to Here. |

[Post Inserter Tray Size Adjustment] | If the size of the paper loaded into the post inserter is not detected correctly, use this option to automatically adjust it so that it is detected correctly. For details, refer to Here. |

To adjust the image density for each color depending on the paper type ([Density Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Density Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the density of images that are printed on thick paper, OHP transparencies, or envelops for each paper type and print color.

To adjust the density of an image that is printed in black and white, select [Black Image Density].

The larger the number, the darker the background.

[0] is specified by default.

To correct the misalignment or tilt of a scanning area in order to stabilize high-quality printing ([Image Stabilization])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Image Stabilization]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Correct the misalignment or tilt of scanning area caused by changes in the temperature or humidity in the machine to ensure high quality printing.

Settings | Description |

|---|---|

[Image Stabilization Only] | Adjusts the displacement or inclination of the scanning section. Select a method for image stabilization and then press Start to execute image stabilization.

[Image Stabilization Only] is specified by default. |

[Image Stabilization Setting] | Change the timing for executing image stabilization as well as the type of image stabilization, as required. Make selection according to the printing frequency and the color/black use ratio.

[Standard] is specified by default. |

To adjust the balance of the paper separation or image transfer performance when a paper jam or image failure occurs during double-sided printing ([Paper Separation Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Paper Separation Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the paper separation position on each side of paper for 2-sided printing.

Adjust balance between the properties related to paper separation and image transfer when paper jams are occurring or images are defective due to the environment being overly hot or humid.

Settings | Description |

|---|---|

[Front]/[Back]/[Thin Paper Front]/[Thin Paper Back ] | Select the paper and side on which to adjust the paper separation. |

[Adjust Value] | Enter an adjustment value between -10.0 and 10.0 mm by tapping [-] and [+]. Increase the value if paper jams are occurring, and decrease it if the image is transferred unevenly. [0.0 mm] is specified by default. |

To adjust a color misalignment caused as the printing result ([Color Registration Adjust])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Color Registration Adjust]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the print position for each paper type with respect to each color if color shifts are detected in the print result.

Load paper into the Bypass Tray and press the Start key to start printing the test pattern. Make adjustments while checking the test pattern. Repeat adjustments as necessary.

The example shows the color registration adjustment for cyan.

Settings | Description |

|---|---|

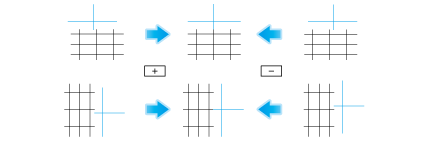

[X] | If the print position of the desired color is out of line to the left or right with respect to the printing position of black, tap [-] and [+] to enter an adjustment value in the range between -6 dots and +6 dots.

[0 dot] is specified by default. |

[Y] | If the print position of the desired color is out of line vertically with respect to the printing position of black, tap [-] and [+] to enter an adjustment value in the range between -6 dots and +6 dots.

[0 dot] is specified by default. |

To adjust to the regular gradation ([Gradation Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Gradation Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Restart this machine.

Check that [Image Stabilization Only] is selected in [Expert Adjustment] - [Gradation Adjustment] and then press Start.

The image stabilization operation starts. Now adjustment items on the right are available for selection.

Select items to be adjusted.

[Print]: Select this option when the printed image has irregular gradation.

[Copy]: Select this option when a copied image has irregular gradation.

Select a paper type for printing a test pattern.

Bypass Tray cannot be selected.

Press the Start key.

A test pattern is printed.

Place the test pattern on the Original Glass in the orientation indicated on the Touch Panel.

Place ten or more blank sheets of paper to prevent bleeding of the test pattern.

Close the ADF or Original Cover.

Press the Start key.

The test pattern is scanned and the gradation level is automatically adjusted.

Repeat Steps 3 to 9 two more times.

To adjust the area to scan an original on the original glass ([Scanner Area])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Scanner Area]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Adjust the scan range of the scanner. For details, contact your service representative.

To adjust the area to scan an original on the ADF ([ADF Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [ADF Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Make adjustments for scanning images in the ADF. For details, contact your service representative.

To configure settings for detecting and cleaning dirt on the slit glass ([Line Detection])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Line Detection]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Set this option for the dirt detection level for the Slit Scan Glass and cleaning of the Slit Scan Glass.

Settings | Description | |

|---|---|---|

[Prior Detection Setting (Front Side)] | Specify whether to issue an alert when the Slit Scan Glass is dirty and set the contamination detection level. | |

[Yes]/[No] | Specify whether to detect dirt on the Slit Scan Glass in advance. [Yes] is specified by default. | |

[Warning Display] | Select the type of alert that is displayed in the Touch Panel.

[TYPE1] is specified by default. | |

[Detection level] | Select a contamination detection level.

[Std.] is specified by default. | |

[Prior Detection Setting (Back Side)] | Specify whether to issue an alert when the Slit Scan Glass for scanning the back side is dirty and set the contamination detection level. | |

[Yes]/[No] | Specify whether to detect dirt on the Slit Scan Glass in advance. [Yes] is specified by default. | |

[Warning Display] | Select the type of alert that is displayed in the Touch Panel.

[TYPE1] is specified by default. | |

[Detection level] | Select a contamination detection level.

[Std.] is specified by default. | |

[Warning Display Time] | Select a timing for displaying a warning message when [TYPE3] is selected for [Warning Display]. [During the Back Side Scan] is specified by default. | |

[Feed Cleaning Settings] | Specify whether to clean the Slit Scan Glass when scanning an original in the ADF. [Clean] is specified by default. | |

To register unregistered special paper as user paper ([User Paper Settings])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [User Paper Settings]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Register special paper with [User Paper 1] through [User Paper 6]. Configure setting for the basic weight and media adjustment.

For details, contact your service representative.

To specify how to erase the area other than the original when enabling [Non-Image Area Erase] for copying ([Erase Adjustment])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [Erase Adjustment]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

Specify the operation and erase method when erasing the area outside the original by setting [Non-Image Area Erase].

Settings | Description | |

|---|---|---|

[Non-Image Area Erase Operation Settings] | Specify how to erase the area outside the original when making copies with [Non-Image Area Erase] set to [ON]. | |

[Erase Operation] | Select either the option for erasing the non-image area by the optimal method automatically selected for the background density of the original or the option for erasing by the pre-specified method. [Specify] is specified by default. | |

[Erase Method] | Select an erase method after selecting [Specify] for [Erase Operation].

[Rectangular] is specified by default. | |

[Original Density] | Adjust the density of the original. | |

To directly print CMYK data without using a simulation profile when printing data using the PS driver ([PS Designer Settings])

To display: >>View

- [Utility]

- [Administrator Settings]

- [System Settings]

- [Expert Adjustment]

- [PS Designer Settings]

- [Expert Adjustment]

- [System Settings]

- [Administrator Settings]

This option is available when [Simulation Profile] for the PS driver is set to [Auto].

Selecting [No] uses a simulation profile based on your processing to correct an entered image with the same density as when an image is output using the PCL driver.

Selecting [Yes] does not use a simulation profile to output CMYK data.

[No] is specified by default.

You can specify the default setting for a simulation profile to be displayed on the printer driver. For details on how to configure the settings, refer to Here.